systems of

management,

monitoring

and diagnostics

production

and engineering

Сomplex systems of automated management, control and diagnostics of electrical equipment for railway transport

About

SCIENTIFIC PRODUCTION

ENTERPRISE

UKRTRANSMASH

Our goal

Find solutions to increase the reliability and efficiency of railway transport electrical equipment

We are focused on innovation.

We work on improving technologies. We guarantee the highest quality of our products

Our

products

Products of SPE UKRTRANSMASH meet the highest quality standards

We are attentive to the needs of our customers. We find the best technical solutions. Always ready for mutually beneficial cooperation

Products UKRTRANSMASHEngineering

Development of sets of electrical equipment according to the customer’s technical requirements

Coordinating the operation of the set of electrical equipment with co-executors

Development of electrical schemes of vehicles according to the customer's technical requirements

Selection of co-executors and performance of the functions of the main executor according to the customer's requirements

Development of technical, design and operational documentation

Participation in commissioning, acceptance, and operational tests, both at the customer's site and at test ranges

Technical support for the supplied systems throughout the entire service life

Systems UKRTRANSMASH

Our experience

— implemented

in new projects

IMPLEMENTED

PROJECTS

01.

2ТЕ10М - 3589

Mainline freight locomotive

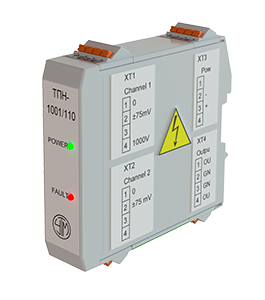

A comprehensive modernization of the locomotive was carried out, including the use of a modern diesel engine, traction unit, and power equipment. The electric transmission scheme was also modernized using the Power Transmission Regulation and Control Unit (BRUEP). With the help of a modern driver's controller and feedback sensors, the BRUEP unit implements efficient control of the electric transmission using the latest control algorithms

For the automatic control of auxiliary equipment, its monitoring, locomotive parameter monitoring, and their display during operation, a Microprocessor Control and Diagnostics System (MSKD) was installed

The modernization of the locomotive was carried out jointly with the Mykolaiv Diesel Locomotive Repair Plant

02.

TEM2 - 8907

Shunting diesel locomotive

The modernization of the shunting locomotive was completed, including the replacement of the diesel engine and the installation of a modern traction unit. The electric transmission was modernized using Power Transmission Regulation and Control Unit (BRUEP)

Efficient control of the electric transmission is implemented by the BRUEP unit with the help of a modern driver's controller and feedback sensors using the latest algorithms

The locomotive modernization was carried out jointly with the Mykolaiv Diesel Locomotive Repair Plant

03.

ТEM2MP - 137

Shunting diesel locomotive

The modernization of the shunting locomotive was completed, including the replacement of the diesel engine and the installation of a modern traction unit. The electric transmission was modernized using Power Transmission Regulation and Control Unit (BRUEP). Efficient control of the electric transmission is implemented by the BRUEP unit with the help of a modern driver's controller and feedback sensors using the latest control algorithms

To monitor the parameters of the main and auxiliary electrical equipment, as well as the locomotive parameters, and to display them during operation, the Microprocessor Control and Diagnostics System (MSKD) was installed to manage the auxiliary electrical equipment

The locomotive modernization was carried out jointly with the Poltava Diesel Locomotive Repair Plant

04.

TEM7 - 0145

Shunting diesel locomotive

The modernization of the shunting locomotive was completed, including the replacement of the diesel engine and the installation of a modern traction unit. The electric transmission was modernized using Power Transmission Regulation and Control Unit (BRUEP)

Efficient control of the electric transmission is implemented by the BRUEP unit with the help of a modern driver's controller and feedback sensors using the latest algorithms

The locomotive modernization was carried out jointly with the Mykolaiv Diesel Locomotive Repair Plant

05.

DPKr3 - 002

Regional diesel train

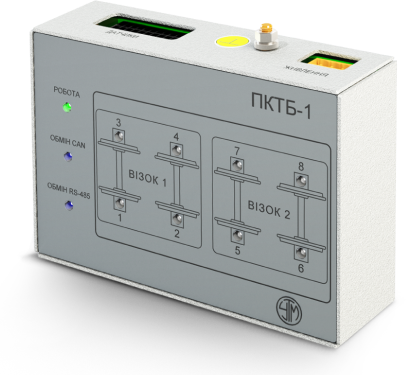

During the production stage of the diesel trains, our specialists installed the Temperature Monitoring Device. The PKTB device measures the temperature of the bearings to prevent overheating

The PKTB device measures the temperature of the bearings to prevent overheating

The work was carried out jointly with the Kryukov Railway Car Building Plant

Our

partners

- Zeppelin Power Systems01

- Baltic Loco Group02

- General Electric03

- Hyundai Rotem04

- Skoda Vagonka05

- Bombardier06

- AS «DLRR»07

- Cummins08

- PJSC «KEVRZ»09

- PJSC «KVBZ»10

- LLC «MTRZ»11

- LLC «PTRZ»12